A LiuGong vai apresentar ao público uma nova linha de produtos na linha de maquinário de construção. Presente na atual edição da feira Bauma, em Munique, a companhia chinesa traz entre seus lançamentos 6 novas escavadeiras. As máquinas vão de 15 a 50 toneladas e juntas compõe a nova linha E-series da LiuGong, chamada de Tier IV. O lançamento compreende os modelos de escavadeira 915EIV, 925EIV, 933EIV, 939EIV, 922EIIIB e 950EIIIA, todas equipadas com um sistema hidráulico novo e obedecendo às leis de emissão de poluentes da União Européia.

Além da nova linha de produtos da Tier IV E-series, a LiuGong também apresentará 14 outras máquinas, entre caminhões-guindaste, motoniveladoras, rolos compressores e pavimentadoras.

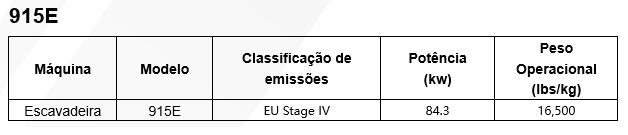

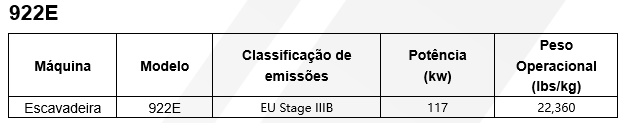

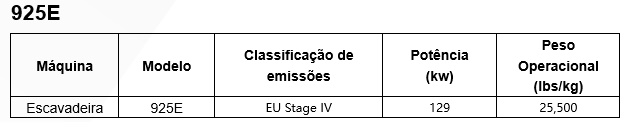

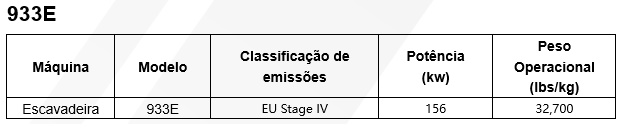

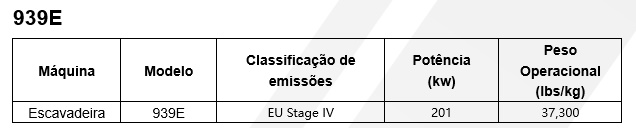

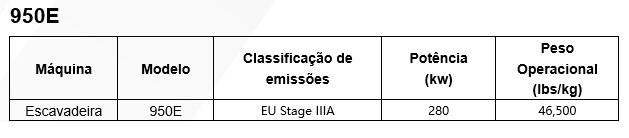

Confira os dados técnicos da nova linha de escavadeiras da empresa:

- The 915E model is equipped with a fuel-efficient world-class Cummins QSB4.5 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes: Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end, whilst also decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.

- Miller R4 tilt coupler and the 48’ bucket are available to meet your various working requirements.

- The 922E model is equipped with a fuel-efficient world-class Cummins QSB6.7 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes, Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Proven negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end while decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.

- Miller R6 power latch coupler and tilt ditching bucket are available to meet your various working requirements.

- The 925E model is equipped with a fuel-efficient world-class Cummins QSB6.7 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes, Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Proven negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end while decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.

- The 933E model is equipped with a fuel-efficient world-class Cummins QSB6.7 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes, Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Proven negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end while decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.

- Miller R7 power latch coupler and MGB 1800 hydraulic breaker with bracket are available to meet your various working requirements.

- The 939E model is equipped with a fuel-efficient world-class Cummins QSL9 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes, Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Proven negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end while decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.

- Miller R8 Power latch coupler is available to meet your working requirements.

- The 950E model is equipped with a fuel-efficient world-class Cummins QSM11 engine, which is further complemented by a Cummins-patented turbochar This varies airflow to precisely match engine and load demand, resulting in optimal performance.

- It has six selectable working modes, Power, Economy, Fine, Lifting, Breaker and Attachment to optimise performance and fuel consumption in every situation.

- The advanced IPC (Intelligent Power Control) system makes full use of engine oil consumption characteristics, matching the engine-hydraulic pump to achieve high efficiency and economical fuel consumption.

- Proven negative flow hydraulics optimise the main control valve, improving the speed of the cylinders’ front end while decreasing the hydraulic system’s damper loss, leading to enhanced working efficiency. The pilot valves match up with the main control valve to offer more precise control.

- The boom and arm support structures are designed with large cross-sectional areas and one-piece steel castings to guarantee their long-term durability and high resistance to bending and torsional stress.

- A reinforced bridge frame increases the overall strength of the machine, as well as its impact resistance. ROPS (Roll Over Protective Structure) cabs meet the ISO 12117-2 safety standard.